Recently, I had the privilege of participating in a panel discussion with Martin Kahl, Owner at Kovetic and Host of “Ride: the Urban Mobility Podcast,” and Amir Tirosh, COO of StoreDot Ltd at the MOVE EV Conference, where industry leaders gathered to explore the exciting advancements in #electricvehicle (EV) technology. The conference provided ample opportunity for conversation and ideation around where the future of EV batteries are headed and the technologies that will help enable the transition to EVs.

Recently, I had the privilege of participating in a panel discussion with Martin Kahl, Owner at Kovetic and Host of “Ride: the Urban Mobility Podcast,” and Amir Tirosh, COO of StoreDot Ltd at the MOVE EV Conference, where industry leaders gathered to explore the exciting advancements in #electricvehicle (EV) technology. The conference provided ample opportunity for conversation and ideation around where the future of EV batteries are headed and the technologies that will help enable the transition to EVs.

At Dow MobilityScience, we are at the forefront of enabling this transition, focusing on innovative technologies that contribute to automotive safety, circularity, and manufacturing efficiency. And we believe that material science will be instrumental in helping overcome one of the greatest hurdles that the industry is facing today when it comes to expediating the adoption of EVs – fast battery charging.

Defining fast charging is an ever-evolving process. Currently, it refers to the ability to charge from 20% to 80% within 20-30 minutes. However, as technology progresses, customer expectations will grow, aligning EV charging more closely with refueling experiences for traditional gasoline vehicles.

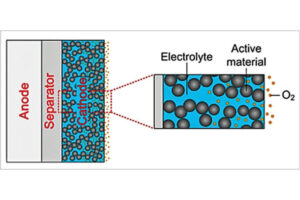

The performance of the materials must be taken into consideration by battery designers and original equipment manufacturers (OEMs) not just during individual charging cycles but also throughout thousands of charging cycles under various situations. While material choices internal to the battery cell, such as the anode and cathode active materials and formulations, the separator, and the formulated electrolyte are all critical choices to achieve appropriate range, safety, lifetime, and cost, all components of the battery system must be carefully considered.

To enable fast charging, effective thermal management of the battery and peripheral components are crucial. As a materials science company, Dow focuses on materials with multiple functions including appropriate thermal conductivity combined with excellent adhesion, toughness, and durability, for example. These properties must endure throughout the battery’s life span and across varying environmental conditions. Designing for recycling and reuse also becomes essential as the need for resource conservation increases, opening new markets for the materials that support such #sustainability initiatives.

Battery safety is also paramount. We invest considerable effort in creating materials that prevent thermal propagation between cells in the event of thermal runaway. Through the development of foams, rubbers, and coatings, we strive to achieve enhanced safety standards for EV batteries.

Fast charging will be a key driver for the mass acceptance of EVs across the United States, particularly in urban areas with dense populations and few public transportation options. We can help facilitate the adoption of EVs on a large scale by addressing the many charging needs that exist across various environments and situations. And by embracing materials science challenges and opportunities, we can unlock the full potential of EV battery charging and shape a cleaner, greener future for mobility.